Waterjet cutting is a popular method of cutting materials such as metal, stone, and glass. It uses a high-pressure stream of water mixed with abrasive particles to cut through the material. One of the key aspects of waterjet cutting is the waterjet pattern. In this article, we will explore what waterjet patterns are, how they are created, and how they can be used to achieve different cutting results.

What is a Waterjet Pattern?

A waterjet pattern is the shape and size of the stream of water that is used to cut the material. The pattern is created by the nozzle that directs the water and abrasive particles onto the material. The size and shape of the pattern can be adjusted to achieve different cutting results. For example, a narrow pattern is used for precision cutting, while a wider pattern is used for faster cutting.

How is a Waterjet Pattern Created?

A waterjet pattern is created by the nozzle that directs the water and abrasive particles onto the material. The nozzle is made up of a small orifice and a mixing chamber. The water and abrasive particles are mixed in the mixing chamber and then forced through the orifice at high pressure. The size and shape of the orifice determine the size and shape of the waterjet pattern.

Types of Waterjet Patterns

There are several types of waterjet patterns that can be used for different cutting results. The most common types of waterjet patterns are straight, fan, and taper.

Straight Pattern: A straight pattern is a narrow, straight stream of water that is used for precision cutting. It is commonly used for cutting intricate shapes and designs.

Fan Pattern: A fan pattern is a wider stream of water that is used for faster cutting. It is commonly used for cutting larger pieces of material.

Taper Pattern: A taper pattern is a stream of water that gradually widens or narrows. It is commonly used for cutting materials at an angle or for creating beveled edges.

Applications of Waterjet Patterns

Waterjet patterns can be used for a variety of cutting applications. Some of the most common applications include:

Metal Cutting: Waterjet patterns can be used to cut a variety of metals, including steel, aluminum, and titanium. They are commonly used in the aerospace and automotive industries.

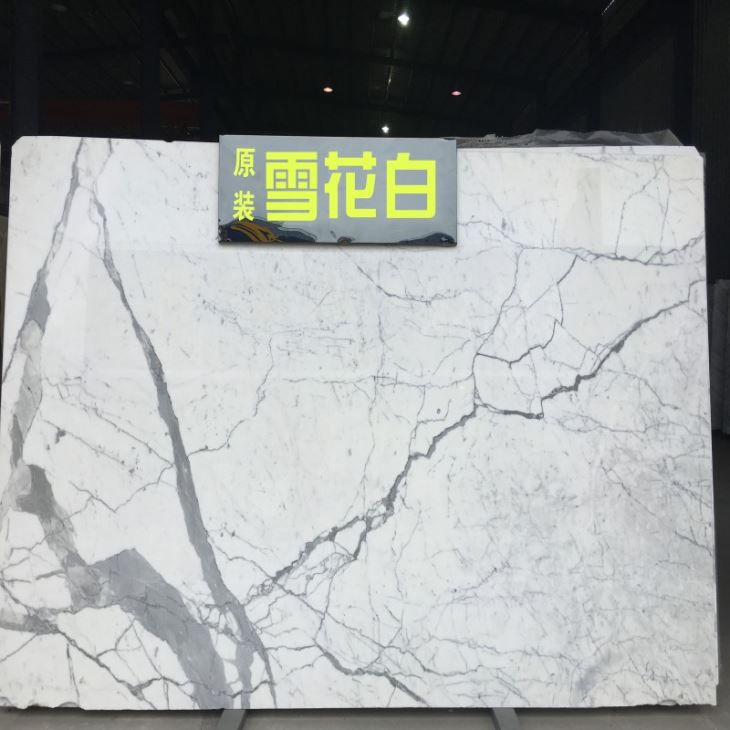

Stone Cutting: Waterjet patterns can be used to cut a variety of stones, including granite, marble, and limestone. They are commonly used in the construction and architectural industries.

Glass Cutting: Waterjet patterns can be used to cut a variety of glass, including tempered glass and laminated glass. They are commonly used in the automotive and architectural industries.

Conclusion

Waterjet patterns are an important aspect of waterjet cutting. They determine the size and shape of the stream of water that is used to cut the material. By understanding the different types of waterjet patterns and their applications, you can achieve the desired cutting results for your specific project. Whether you are cutting metal, stone, or glass, waterjet cutting is a versatile and precise method that can help you achieve your cutting goals.

Related Products